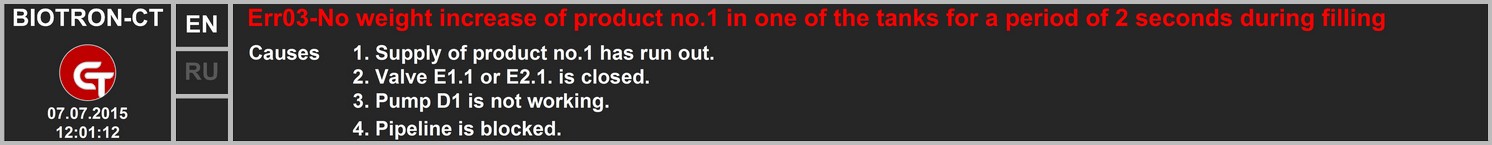

Modern dosing systems, used by other companies are not able to guarantee the steady dosing of source ingredients if ambient conditions (temperature, liquid level in source ingredients and prepared products tanks, oil viscosity, etc.) change. The system which our company has designed does not include these disadvantages and has an extremely high dosing precision – 0.1%. In addition, the system is equipped with a pre-mixing unit, there is the option of adjusting flow rate and pressure at the system output and there is also a source components dosing feature. The equipment uses original software and high-reliability electronics produced by the company FANUC. The PPS-CT 1200 system also includes a biodiesel fuel production safety tracking function. The processor tracks the source component availability, their filling speed, mixing intensity, ability to pass through pipelines and valves, etc. If there is an emergency, the processor will stop the whole system; send an audible signal to operator and show the error code on the display, together with a detailed description and possible causes. In this way, for example, if there is an oil shortage in the source products storage, the following message will be displayed: